Machinability & Machinability Rating. What are the best & worst Materials to machine based on Machinability Rating ?

What is Machinability and Machinability Index or Rating ?

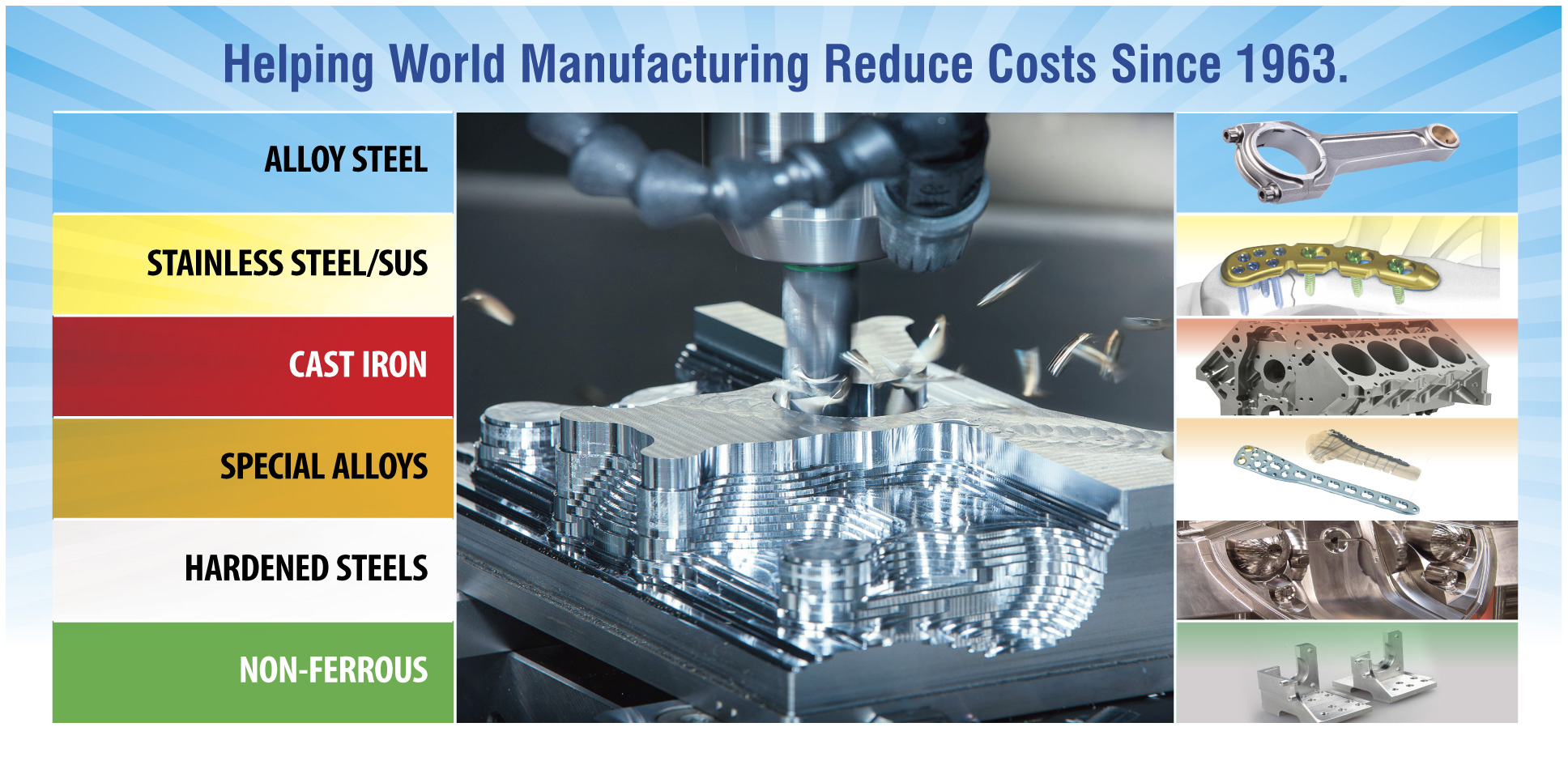

Machinability is the ease with which a Cutting Tool can machine a workpiece material. Machinability ratings (MR) provide understanding of the severity of a metalworking operation in comparison to B1112 steel as the base material whose MR is taken as 1.0. So Lower the MR poor is the machinability of the material ; materials like M-308 (0.05), M-252 (0.05), Inconel 700 (0.09), Inconel 901 (0.09), Hastelloy X (0.09), Udimet 500 (0.09), Haynes Stellite (0.12), Nimonic 80 (0.12), Waspalloy (0.12) are some of the worst materials for Cutting Tools as there machinability rating or index is by far most poor of all materials. Hence they will consume your Cutting Tools like Crazy... So whenever working with these materials keep in mind the cost of tooling will go up substantially instead of your general Stainless Steel Or Alloy Steel Or Hardened Steel tooling costs. Hence a lot of times new machinist make this mistake of Under-quoting on these materials as they do not take into account the Machinability Ratings of the materials they are machining. So do not make that mistake , as it can cost you dearly !

Factors affecting machinability include tool material, feeds, speeds, cutting fluids, and the microstructure, grain size, heat treatment, chemical composition, fabrication methods, hardness, yield strength, and tensile strength of the work piece

Machinability (Tool Life)

The Taylor tool life equation describes the expected tool life of a cutting tool as a function of cutting speed

The table below shows the MR - Machinability Ratings of almost all the general materials under machining, if you do not find any material here please do let us know we could add the same here for everyone's help.

For More blogs on Carbide Tools Application, Usage and Best Industry Practices you can

Click Here